GTR Nest Manager powered by PASCAM Bea

The PASCAM nested based solution - 'GTR Nest Management powered by PASCAM Bea' - is an automatic nesting and CNC programming solution, especially developed to run on CNC machining data, delivered by PASCAM Bea, to control nested based woodworking on CNC machining centers from within your familiar SOLIDWORKS® CAD interface. It is a smart and easy to use addition to the PASCAM toolbox of woodworking solutions to program single or multi-spindle wood routing machines in 2D profile cutting applications. The program is ideal for high efficiency production at interior decorators and shopfitters, at boat builders, as well as furniture manufacturers.

The GTR Nest Manager nesting process in detail:

GTR Nest Management is performing true shape nesting, where the

parts required can be any odd shape. The individual parts are

created using

PASCAM WoodWorks and

PASCAM Bea, based on

SOLIDWORKS®, then a .xml file is generated by

PASCAM WoodBatch, to kick off the

nesting optimization by the GTR postprocessor.

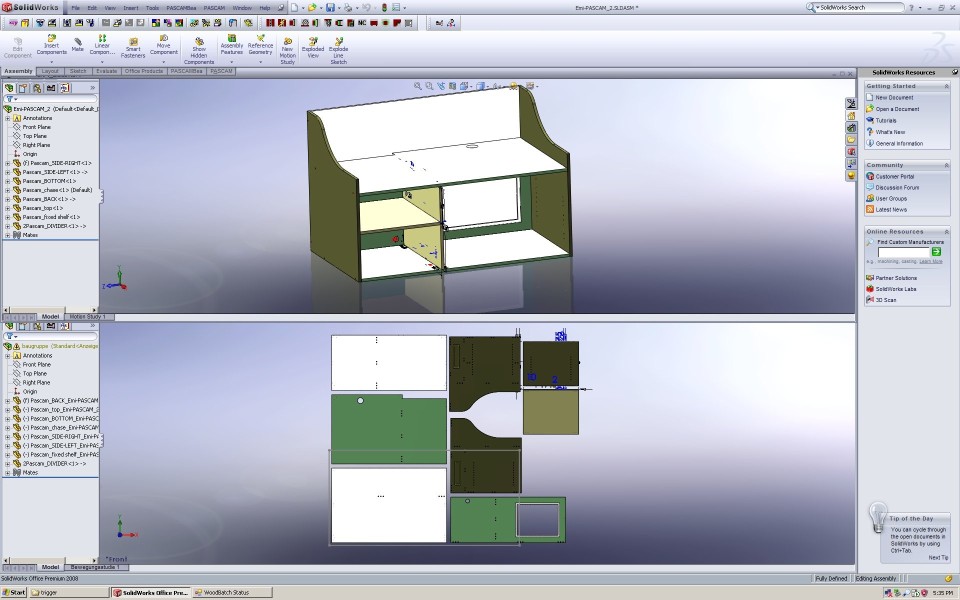

For example a 3D assembly model of a cabinet (see picture below) can

be created with the PASCAM WoodWorks Part description in SOLIDWORKS®. Using GTR Nest, this assembly is

unfolded into the cabinet's flat case parts on the raw sheet, while

considering the correct compliance of the material type, the

material thickness and the grain direction of the raw sheet with the

model parts. The flat case parts can then be nested and the CNC code

is generated with our woodworking CAM module PASCAM Bea for profile

cutting for optimal material utilization. As an alternative, the

nesting job editor can be started directly from the application. Any

subsequent changes are then stored in a file. The "ReNest" function

will then launch a fresh nesting job and create a XML file for the

machine control, including those adjustments.

Based on PASCAM Bea's superior CAM programming technology and the woodworking engineering enhancements delivered by PASCAM WoodWorks, the powerful nesting technology in GTR Nest Management enables the safe and reliable extraction of manufacturing data and generation of CNC code for true shape nesting, based on 3D SOLIDWORKS® model assemblies.

By the GTR Nest Manager's true shape nesting algorithm, GTR Nest supports among other things bridges, "onion skin" cutting, parts in parts and remnant nesting with small part threshold nested in the center of the sheet.

The GTR Nest Management true shape nesting gives you the power to:

- Manage the raw material boards are using a sheet stock. Sheets can be manually selected from this stock for nesting. As an alternative the program can retrieve suitable boards automatically from the sheet stock.

- Nest the parts automatically, according to the job order. The nesting job is created by dissolving the SOLIDWORKS® assembly.

- Manually compile the nesting job. The nesting job can take place per job or per order (as a SOLIDWORKS® assembly) or via a arbitrary part compilation..

- Test the material thickness, material type and grain direction of the raw board and the model parts for correct conformity.

- Print out of the nesting results as a drawing.

Additionally there is a facility to print out of freely configurable adhesive labels, including the print out of the drawings. And there are also powerful, enhanced part retention methods available:

- Automatically preventing milling through at small parts, as of a certain workpiece size (onion skin). Parameter: Remnant thickness

- Automatically adding or setting of bridges (depending on the workpiece size). Parameter: Length, Number and Thickness of bridges

- Automatically positioning of small parts in the centre of the raw board (if the workpiece size is smaller than a certain threshold value the part is placed at the center of the sheet). Variable: Prohibited boundary

GTR Nest Manager business benefits:

GTR Nest is supporting nesting jobs on any capable woodworking CNC

router machine. Especially if you are operating CNC machines from more

than one vendor, you will save a lot of money using GTR Nest Management

to control the different machines with a single work seat installation.

Saving not only additional license fees but also on training and support

costs for your staff, due to staying in the SOLIDWORKS® CAD

environment and not having to learn several different software packages

of 3rd party vendors.

Automatic nesting ensures optimal utilization of material, allowing more

parts to be produced from less material. Machine motion optimization

using advanced PASCAM Bea CNC programming ensures minimum machine cycle

time, increasing the production capacity of your existing equipment.