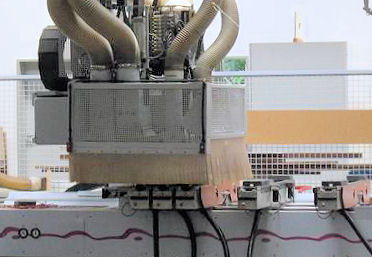

CNC machine coupling

PASCAM Bea follows new ways at the generation of CNC-data and CAM programs. We provide the capability to directly program all common woodworking CNC-machines from within SOLIDWORKS®. The machine-neutral CNC-data generation and subsequent postprocessor specific parameter specification in PASCAM Bea is enabling the control and CAM program generation for multiple machines from different woodworking CNC machine manufacturers from a single PASCAM Bea seat. PASCAM Bea offers the most exhaustive set of CNC machining strategies available today. From CNC machining centers with edgebanding capabilities to nested based routers or through-feed machines, PASCAM Bea offers woodworking companies full control over all their manufacturing data.

Besides the capability to process and edit the CAM data completely in this integrated 3D CAD/CAM system, you also still have the option to modify the CNC data quickly and flexibly on the machine by using the interfaces of the well established systems mentioned below:

| woodWOP

|

|

and

|

Since a local CNC programming system, which is directly installed on the machine, would not take into account the separate modifications to the CAM features which are stored at the underlying product model, a machine-oriented CAM workstation, equipped with PASCAM Bea (see hereto our PASCAM Machine Edition offer) can provide a fast feedback of this modified data at the original product model in which the changes to the CNC features will be merged correctly. This approach is more safe and efficient for all parties involved in the manufacturing process to apply practice-proven CAM features at subsequently new or modified CNC programs than ever before. It allows also to use the advanced features of this powerful, proven CAM programs at its best. Strictly according to our philosophy: Run the best!

Your benefits at a glance:

- No more inefficient and error-prone multiple programming of CNC machines, CNC machining centers and production lines

- Fully integrated CNC programming interface with feature technology; independent from the user interface and the scope of performance of the genuine CNC machine control

- Effective knowledge management on practically proven CNC features at the user company, based on user-defined CNC feature databases

- Reduced training costs for CNC programmers - each programmer can control any CNC machine in a heterogeneous machine park at the highest level

- Reduced interface costs - all CNC master data is running through PASCAM Bea with highest data quality

Get more detailed information on our powerful CAM partners by clicking on the company logos depicted above or at the link 'CNC machine coupling' at the navigation frame on the right or see our CAM partner page.